1. Advanced Water Treatment Workshop

The quality of water determines the quality of edible ice. To ensure our ice is pure and slow-melting, CBFI provides an advanced water treatment system. Our water treatment workshop is equipped with RO water treatment systems and multiple filtration devices to meet the highest standards of edible ice.

2. Automated Ice Production Workshop

Our cutting-edge ice-making system and automated production line cater to various types of edible ice, such as tube ice and cube ice. The produced ice is free from chemical additives, pure, and clear, with enhanced melt resistance and better taste.

3. Ice Cup Production Workshop

Our production workshop maintains strict control over low-temperature environments to ensure product quality. Popular cup sizes include 240g per cup, with a daily output of up to 500,000 cups. Customization is welcome.

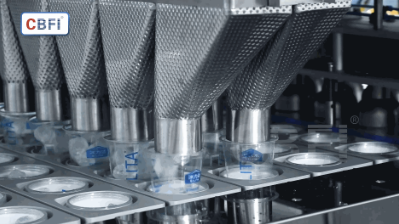

Filling System

Image Placeholder

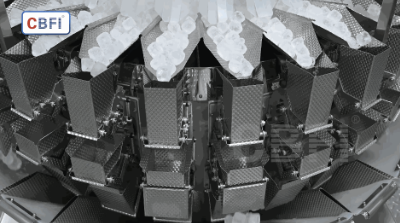

Dried ice cubes are transported via conveyor belts into ice hoppers. The intelligent multi-head weigher ensures precise measurement and packaging, with sensitive detection of ice cube entry to maintain consistency in output.

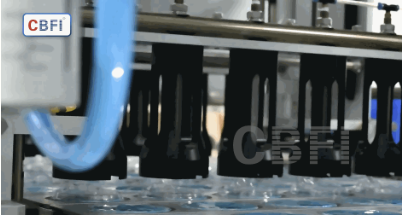

Dispensing System

The dispensing system synchronizes with the conveyor system, accurately dropping ice into cups. It ensures smooth ice flow without blockages and accommodates various ice specifications to meet diverse needs.

The production line is highly integrated, with sanitary observation panels for hygiene reliability. Its modular design allows for easy daily cleaning, installation, and disassembly.

Sealing System

Our special heat-sealing technology ensures the cup mouth is tightly sealed, clean, and hygienic. A mechanical arm then places a direct-drinking cap, completing the ice cup production process.

4. Packaging Workshop

Once the ice cups are made, they enter a highly automated packaging process, which includes automated boxing, sealing, metal detection, palletizing, and wrapping for storage. The entire operation is mechanized and intelligent. Automated Boxing, Sealing, and Metal Detection. Automated Palletizing, Pallet Distribution, Wrapping, and Storage

5. Storage Cold Room

After packaging, the ice cups are transported by forklifts to the cold storage for preservation or distributed via cold chain logistics to supermarkets, convenience stores, and other locations in need of ice cups.

The modular design of the cup ice production line ensures high integration and easy maintenance, whether it's cleaning, assembly, or disassembly.

Product Excellence

Adhering to standardized production principles, we continuously lead innovation in the edible ice industry, setting new benchmarks and heights in industry standards!