CBFI Solid Tube Ice Machines with Full Cylinders ices

Hot Sale Economic Solid Tube Ice Machine (with flat cut ends) Full cylinder ice

10-30tons Freon/Ammonia System

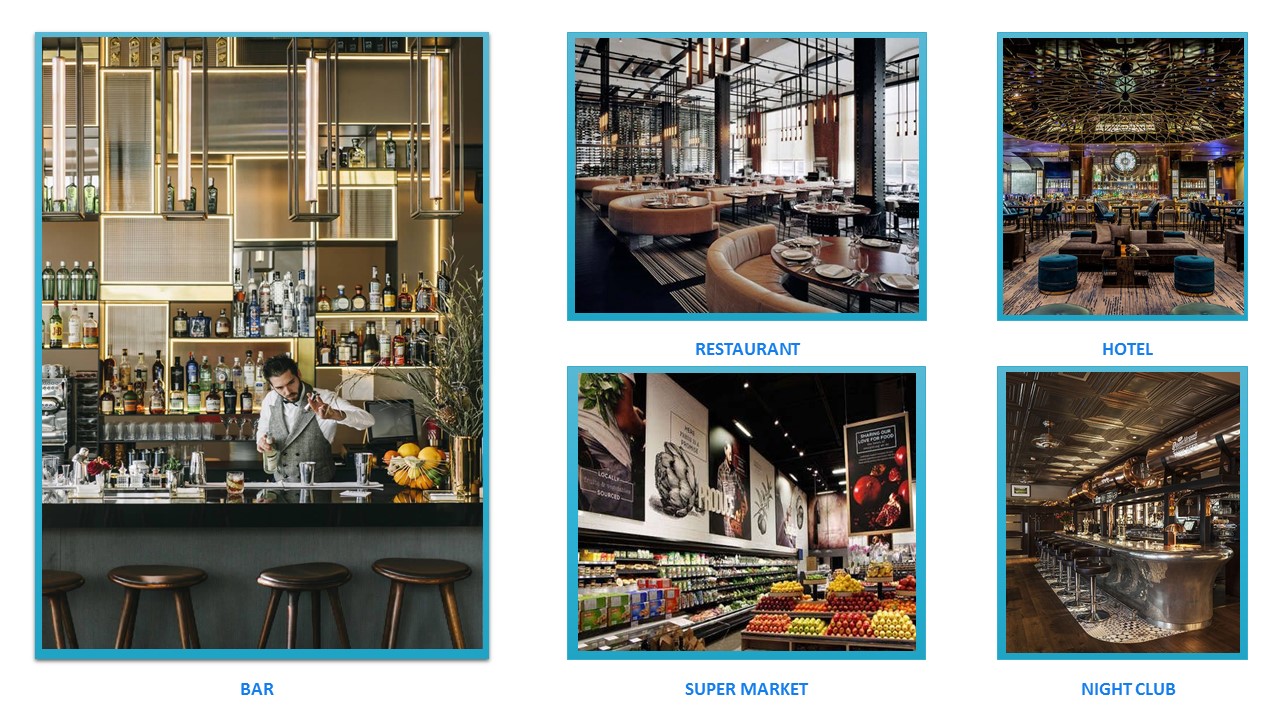

Market introduction

Recent years, there has been a trend in the European and American edible ice market. The ice must be exquisite in appearance and strong in melting resistance. Then, solid tube with saw-cut was born. The ice has no holes in the middle, and the melting time is much longer than that of ordinary ice tubes. , The finished alcoholic drinks have a good taste, consumers can taste the original taste of alcoholic drinks, and the ice tube have a high ornamental value.

In the next few years, solid tube with saw-cut will gradually be sought after by people all over the world.

CBFI(Guangzhou Icesource) is the only manufacturer of Solid Tube Ice(with flat cut ends) Machine in China. And the price has an absolute advantage than other manufacturer in Europe. CBFI saw cut(Solid No Hole)Tube ice machines are the the most recently developed model for high requirement ice user. Our special technology allows a solid frozen tube ice with a saw cutting design to produce clear and delicate clear ice cylinders with flat cut ends.

Features of Solid Tube Ice Machine

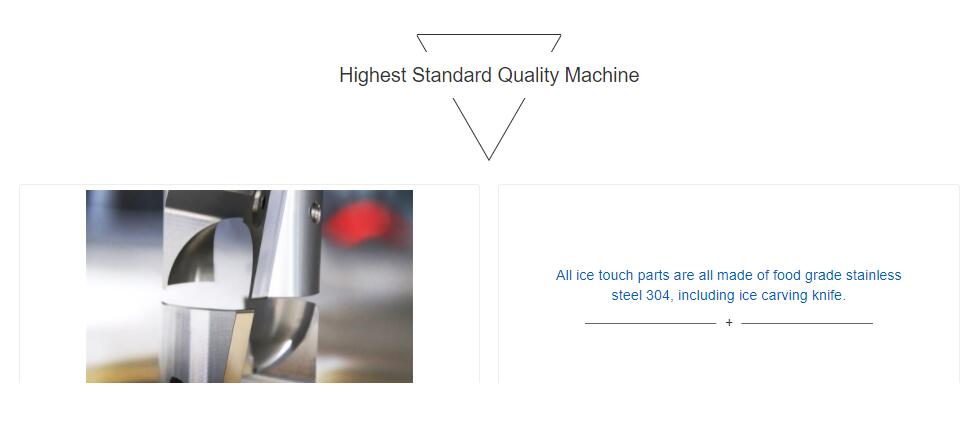

1.Hard, Clear solid tube ice with no hole

2.Cartridge’ saw cutting mechanism-Special designed by CBFI

The exclusive design of solid tube ice with saw cut

a. Patented saw cut technology, ensure the cutting is flat, saw cut rate is above 95%

b. Rust-resistant, Corrosion-resistant and Durable cutting blade, used SUS440C (Scalpel grade material)

c. Patented refrigeration technology, prevents all the problem might brought by the change of load, ensure the stable running of the whole refrigeration system.

d. Exclusive ice making water control system, ensure solid ice rate is above 98%

3.Both ammonia and Freon system are applicable. Capacity range from 10 to 30 tons.

4.Tube-ice 22mm, 28mm, 35mm,41mm Diameter available, other sizes can also be customized according to customer requirement.

Benefit

1.Make higher quality ice to be more competitive in the market,cater for higher quality demand.

2.Higher quality ice for more profit

3.Effective and mass production of quality ice, no molds.

4.Factory tested to assure proper operation and reduce installation time.

China's first 30 ton ammonia machine case in Europe

The customer is one of the largest fully automatic ice factories in Europe. In order to meet the ice demand of the market, the customer choose to cooperate with CBFI, so why CBFI?

1.Because CBFI can provide equipment that meets European CE import and installation standards, it is also the only manufacturer in China that can produce such equipment.

2.Compared with machines of the same quality in Europe, the price has an absolute advantage, reducing customer costs, allowing customers to recover costs in the shortest time and obtain profits.

With the assistance of CBFI professional engineers, the machine was successfully installed and the ice tube have been sold to the European market.

The parameters of the ice machine

Product Parameter

Product Parameter