CV3000 low power cube ice machine is a large-scale production of edible cube ice making equipment. The produced cube ice is clean, hygienic and crystal clear. It is widely used in hotels, bars, restaurants, convenience stores, cold drinks shops, etc. place.

We have experienced team of R & D engineers,supply special size ince machines made as per request.

Brand:

CBFIItem NO.:

CV3000Shipping Port:

Guangzhou PortWarranty:

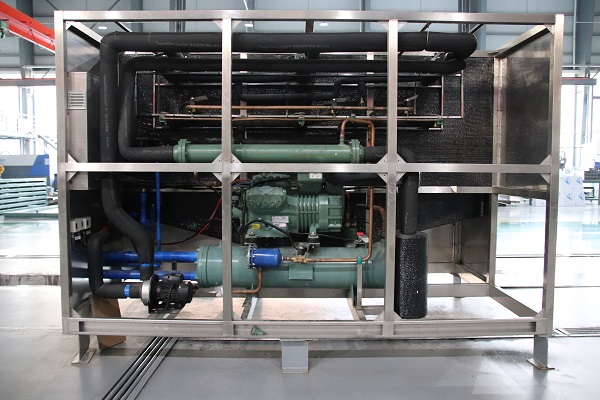

1 yearCBFI CV3000 3 ton per 24h cube Ice Machine

Features of CBFI Edible Cube Ice Machine:

1.Safety and sanitation:The machine is made of 304 stainless steel. The water sink is specially designed to avoid incrustation. The machine also has an automatic cleaning function, to make sure the cube ice is sanitation, safety, and meeting international standards.

2.Low power consumption:Power consumption is 85-90 degrees/ton in summer, if the ambient temperature is below 23 degrees, and the power consumption is 70-85 degrees/ton.

3.Automatic operation:Cube ice machine adopts PLC centralized control, so the machine has the following automatic functions, automatic adjustment of ice thickness, automatic ice formation, automatic ice harvest, and automatic water replenishment.

4.Large ice production:The output of a single machine is stable from 1 ton to 20 tons. Summer output can reach 90%-95%; when the ambient temperature is below 20 degrees, the output can reach 100%-130%.

5.Stable performance:ice cubes are crystal clear, have high hardness, uniform rules, beautiful appearance, long storage time, clean and hygienic, and fully meet the national hygienic requirements for edible ice.

6.Brand accessories:the compressor adopts German Bitzer or Italy Frascold, and the electrical accessories adopt Siemens, LG brand, etc.;

7.Edible ice cube size:22*22*22mm / 29*29*22mm / 38*38*22mm and many other models.

Machine Details

|

|

|

|

|

|

|

|

|

|

|

|

|

Parameters

| CV3000 Cube Ice Machine Parameters | ||

| Name | Unit | Parameter |

| Bitzer Compressor Parameter | Model | 4NES-14 |

| Cooling Capacity(kW) | 30.1 | |

| Power(kW) | 10.58 | |

| Condenser | Model | WN-15 |

| Heat Exchange(kW) | 49.2 | |

| Condensing Temperature | Degree Celsius(℃) | 40 |

| Evaporating Temperature | Degree Celsius(℃) | -10 |

| Ambient Temperature | Degree Celsius(℃) | 32 |

| Water Temperature | Degree Celsius(℃) | 20 |

| Refrigerant | R507 | |

| Voltage | V/P/HZ | 380/3/50 |

| Circulating Pump | Power(kW) | 0.37 |

| Cooling Tower | Model | LX-20 |

| Power(kW) | 0.56 | |

| Cooling Pump | Model | GD50-17 |

| Power | 1.5 | |

| Cooling Fan | Power(kW) | 0.75 |

| Machine Dimension(Water Cooling) | L*W*H(mm) | 1980*1630*1860 |

| Weight | kg | 1200 |

Cube Ice