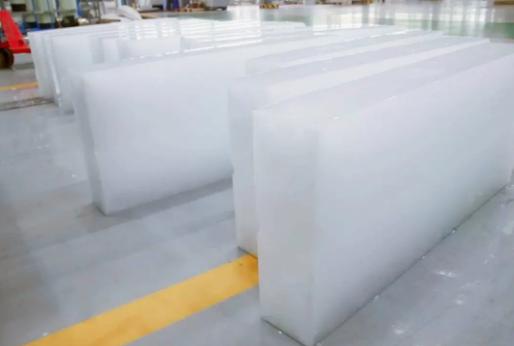

Ice blocks are ice products with the largest external dimensions and the smallest contact surface, making them resistant to melting. They are low-cost, easy to operate, and offer substantial cold storage. Once crushed, their increased contact surface quickly cools food, slows deterioration, and extends preservation time. Ice block sizes can be customized based on bucket dimensions, and they are versatile for various industrial applications.

Ice blocks are ideal for ice factories at ports and docks, food processing, aquatic product preservation, long-distance transportation, and ice sculpture viewing. They are particularly beneficial in areas with high ambient temperatures and unstable voltage.

As society progresses, the demand for large ice blocks continues to rise. Industrial ice is widely utilized in hospitals, schools, laboratories, and food preservation in supermarkets, fisheries, and cold storage. Its applications extend to medical uses, chemical processing, and ice sculptures in amusement parks.

The output of industrial brine ice block making machines from Guangzhou Bingquan Refrigeration Equipment Co., Ltd. ranges from 1 ton to 200 tons, categorized into integrated ice block machines (1 ton - 10 tons) and brine type ice block machines (20 tons - 200 tons).

Today, we highlight the salt water ice block machine.

Unlike smaller integrated machines, the sea water ice block machine features a salt pond constructed with blocks and cement, offering a daily output of 20 tons to 200 tons. Installation requires on-site construction, while the unit and ice molds are pre-assembled in the factory.

The ice making pool is filled with salt water, cooled by the evaporator. Water is added to the ice mold and submerged in the tank, where low-temperature salt water freezes it. When ice is released, molds are fixed in rows, and salt water circulates evenly to enhance freezing speed. The ice is melted briefly before being removed and transported.

Use Less Electricity to Make More Ice

Guangzhou Bingquan’s industrial brine ice block machines utilize a coil design to optimize electricity use. After 10 years of development, we have introduced the second-generation coil ice block machine.

Guangzhou Bingquan Refrigeration has successfully built brine ice block factories in various countries, gaining recognition for its engineering design, product quality, and after-sales service.