Brand:

CBFI1、Production Application

Aquatic product and seafood, hot pot product, meat products, pastry, poultry, ice cream, bread dough fermentation,etc.

2、Sprial Freezer Features

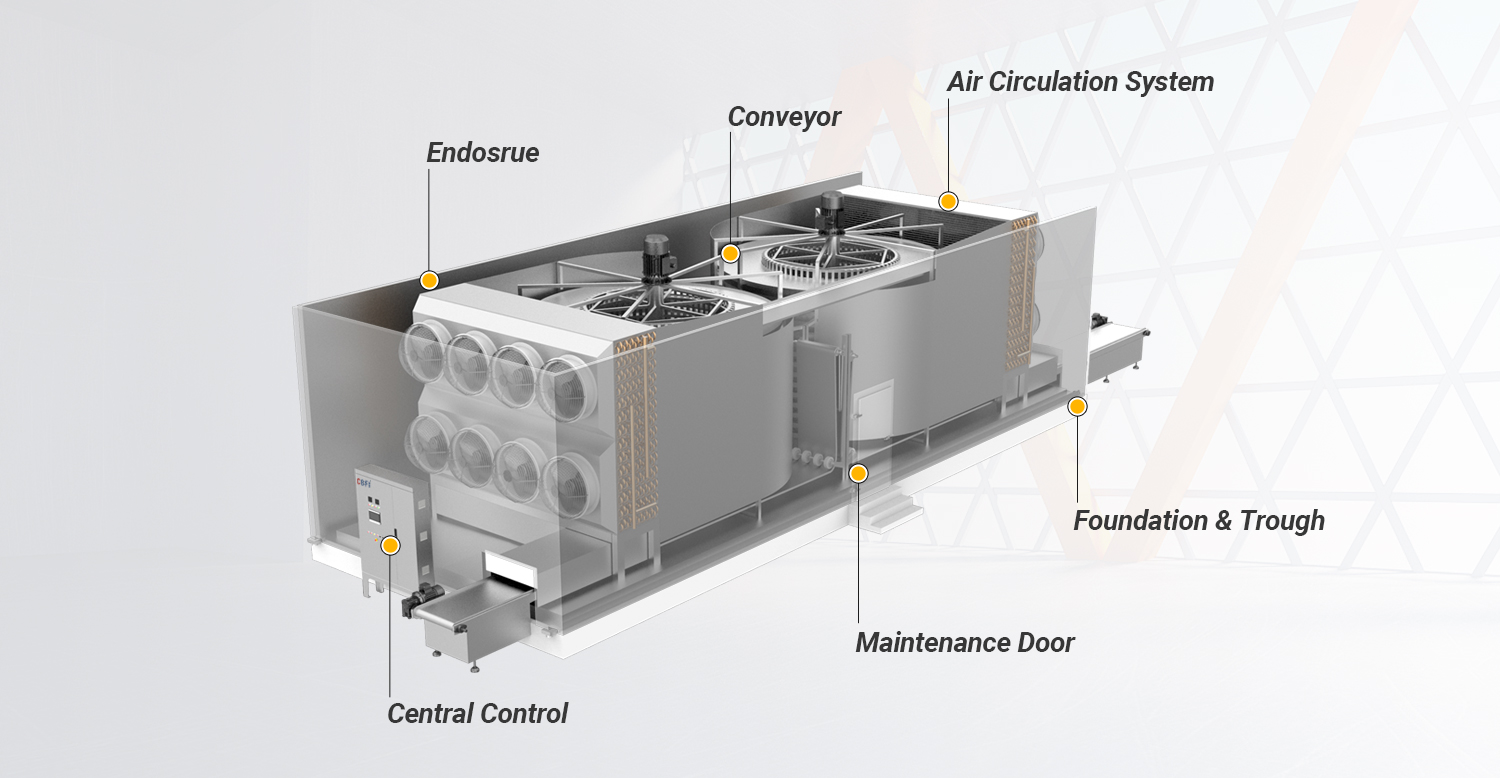

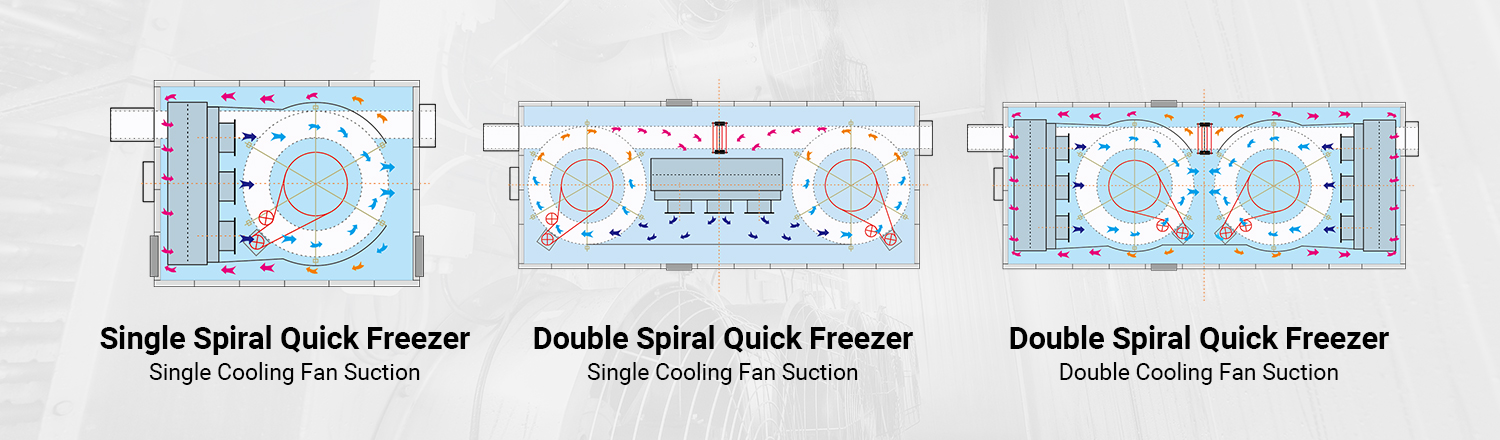

Spiral Quick Freezer is a freezing device with small area, energy saving, high efficiency and large capacity, product is conveyed on mesh belts doing spiral movement inside freezer to make food fast frozen.

Rational Design

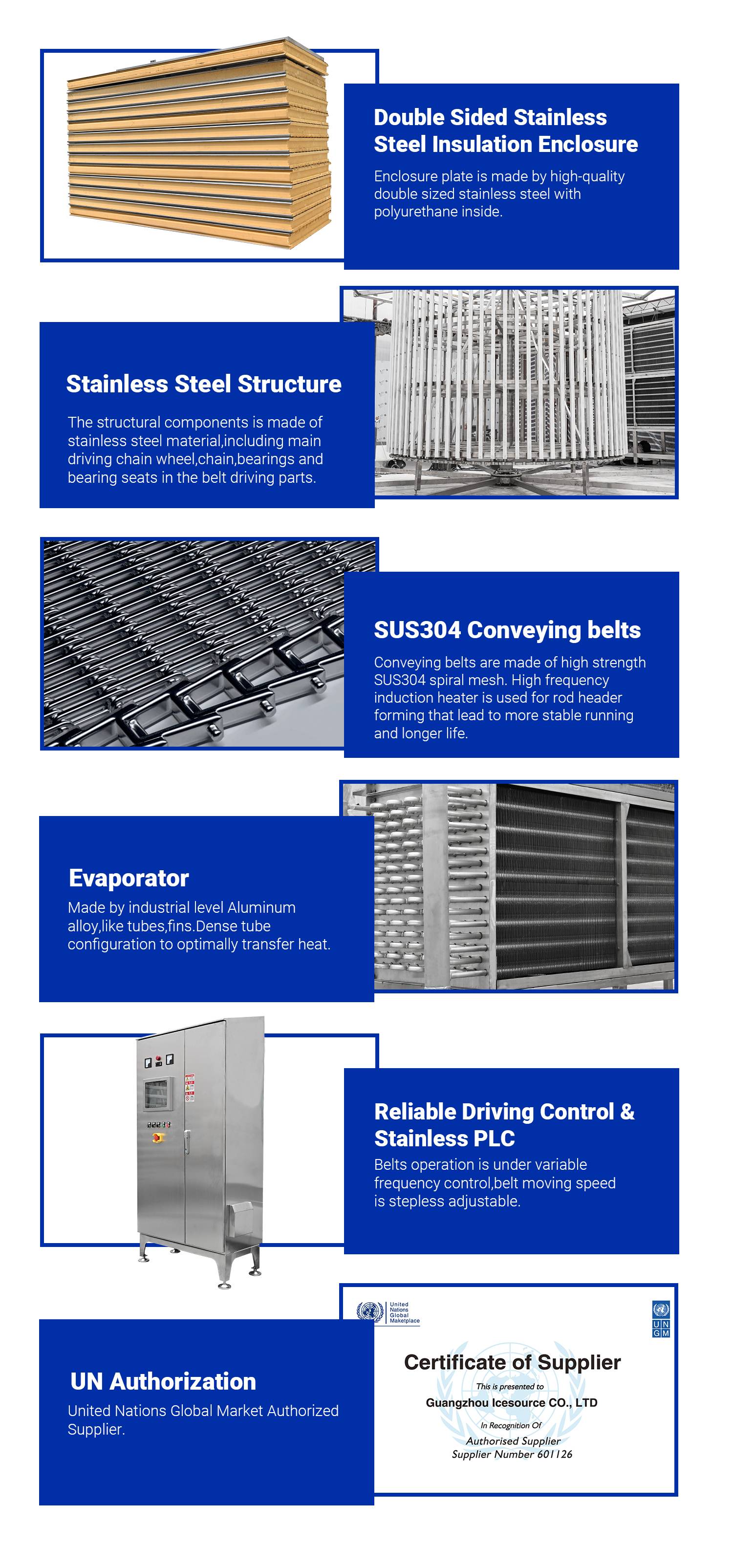

Rational design,safe and reliable running;the design originated from advanced Europe technology. Double protection,both mechanical and electronic, ensures reliable running. Convenient and flexible production operation:more flexible in input and output direction options and also easier to match with other equipment, realizing streamline production.

Simple Operation and Easy Cleaning and Maintenance

Quick freezer can be operated only after simple training,no special requirement. Sloped and fully welded base structure is easier for cleaning and faster drainage.Inside space is larger for easier maintenance

3、Company Profil

Guangzhou IceSource Refrigeration Equipment Co., LTD is founded in January of 2004,which is established on the management and manufacture basic of Guangzhou Vista M&E Equipment Co., Limited. Our factory was located in Panyu District of Guangzhou, Guangdong Province, it is near two famous port of South China Huangpu Port and Nansha Port, and not far from Baiyun airport. It is convenient for load and transport goodsand forcustomers come to visit our factory.

Our company is specialize in research, design, produce and sell large production ice cube machine, ice block machine, ice plate machine, ice tube machine and shaved ice machine, and its accessory equipment, for example cold room, crane, ice crushing machine and so on. Machine's output design can start from single small ice machine for produce 1ton ice per day to large scale completely ice making system for produce 50tons ice per day. All componentsfrom choosing raw material to processing and finished products, all pass strict inspection, strict quality control, ensure completely ice system with excellent quality.

The products are widely applied to different fields, such as food industry, large chain supermarket, retail, aquatic product, chemical industry, water conservancy, power plant health care, large public project, mine cooling, chemical industry, etc. Independent research and design is the source of technology to update, our company has owned two patented technologies: flat-plate heat exchange and circulating heat gas for ice dropping. These two patents have greatly improved the stability and safety of our ice making machine and ensure machine prominently energy saving, its energy saving rate is more than 30%.It start new generation of energy saving product. Icesource products have passed ISO9001, ISO14001 and CE certificate.

We have been keep tracking service condition of our products, have record for more than 400customers in more than 30countries from Africa, Middle East, Southeast Asia Australia and South America. It bring us rich experience and and valuable data to improve our products for different environment condition. Icesource take"painstakingly created high quality products and wholehearted service"as company tenet, keep developing and perfecting our sales system and after-sale service system, Combined with own advantages, continuous learning foreign mature sales experience and cater to domestic and international market trends and demands. Company adhere to the principle of equal emphasis on social and economic benefits. We will try our best offer customer timely and comprehensive service and support.

Icesource adhere people oriented, technology first corporate ideas, view customer's practical needs, improving people life quality and environment for human being existing as a duty. Gathering strong technology, professional talent, and advanced facilities, continuously improve making ice technology, to be leader of ice machine industry.

The company has set up showcases in the Philippines and Malaysia, mainly to provide customers with a comprehensiveand systematic platform for understanding the company's ice machine. At the same time, it can also provide customerswith technical guidance and after-sales service for equipment use.

The company has been engaged in the research and development of refrigeration equipment since 2004. At present, the company's research and development team has more than 60 people, and can provide customers with product customization services. Has a number of patented technologies. The equipment is energy-saving, high-quality high-efficiency, and stable, and has been favored by many domestic and foreign catering, fishery, and medical industries.

The company has a dedicated after-sales service team that can help customers complete the installation and use of the ice machine through telephone, video or installation workers to the site. The complete service system from product production, transportation, installation, commissioning to commissioning has enabled our company to cooperate with many companies.Guangzhou Transportation Group, Beijing Olympic Games, World Expo, Master Kong, Wang Lo Kat, etc. are all customers of our company. Rich trading experience is worthy of your trust.